May 01, 2015

Wellesley, Mass., May 1, 2015 –BCC Research (www.bccresearch.com) reveals in its new report on gas-to-liquid (GTL), coal-to-liquid (CTL) and biomass-to-liquid (BTL) processes, many major oil companies have announced plans to investigate the production of synthetic diesel fuel via a GTL process. A handful of established GTL companies, such as Sasol, Shell, PetroSA, Chevron and Renewable Energy Group, however, are the dominant producers. There are numerous second-tier companies that have sizable GTL support operations in engineering, design, plant construction, ancillaries and related activities.

Liquid GTL products are primarily transportation fuels, which are defined as synthetic fuels or synfuels, as well as chemical feedstocks such as methanol, hydrogen, and other petrochemicals. As the terms are presently used in the petrochemical industry, GTL and GTL products refer mainly to the output of plants or refineries that utilize stranded natural gas as feedstock.

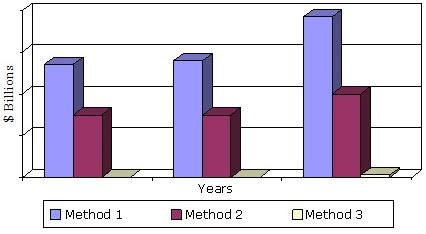

The value of products produced by GTL processes is expected to amount to roughly $5.6 billion in 2015. The market is anticipated to grow at a rate of approximately 6.6% from 2015 to 2020. In the U.S. market, the recent substantial increase in natural gas reserves from shale oil drilling and fracking has created opportunities for lower-cost conversion to liquid fuels and chemicals.

The GTL business is involved in the chemical conversion of stranded natural gas feedstocks to products such as transportation fuels, lubricants and chemicals. As far as beneficial processing of the world’s huge resource base of stranded natural gas is concerned, GTL processing is a relatively recent research and development focus of the petrochemical industry.

“The World Bank estimates that more than 150 billion cubic meters of natural gas are flared or vented annually, an amount worth approximately $30 billion, or equivalent to one-quarter of the U.S. annual gas consumption. All of this wasted resource is potentially available to GTL processing,” says BCC Research analyst Kevin Gainer. “The current strategy in GTL technology is focused on monetizing this huge amount of otherwise worthless remote natural gas deposits.” Natural gas supplies have become even more plentiful of late, thus making gas a potentially low-cost feedstock for the manufacture of fuels and chemical raw materials.

Gas-to-Liquids Processes for Chemicals and Energy Production provides an up-to-date and critical evaluation of the most dynamic and path-breaking aspects of GTL technology. The report also describes the ways in which recent breakthroughs in conversion technology, including notable developments in small-scale GTL production, have made GTL products competitive with products refined from crude oil.

Editors and reporters who wish to speak with the analyst should contact Steven Cumming at steven.cumming@bccresearch.com.

Gas-to-Liquids Processes for Chemicals and Energy Production( EGY021D )

Publish Date: Mar 2015

Data and analysis extracted from this press release must be accompanied by a statement identifying BCC Research LLC as the source and publisher. For media inquiries, email press@bccresearch.com or visit www.bccresearch.com/media to request access to our library of market research.